We're proud of the work we do at Carneil Precision Engineering and we'd like to show you some of it here...

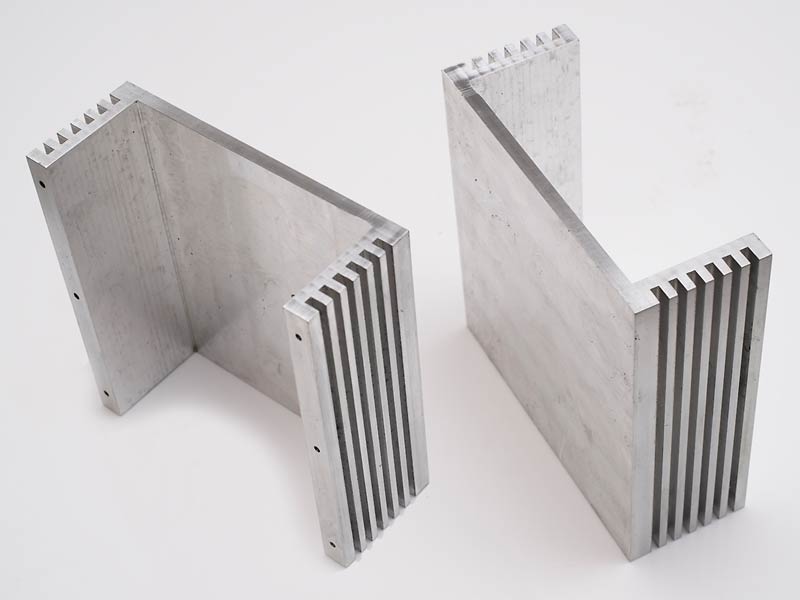

These heatsinks for electronic assemblies were milled using a vacuum work-holding plate allowing multiple parts to be machined at once to save cycle time and cost.

The material used is aluminium 6082T6 and alochrom 1200 provides a self healing, corrosion resistant finish.

Contact Us for a quote or simply to discuss your requirements.

These sensor housings were machined from 316 stainless hexagon stock and once again the process was designed for efficiency and fast turn-around.

Using the Miyano 4 axis bar-fed lathe this part is machined in one hit.

Contact Us for your steel and stainless steel components.

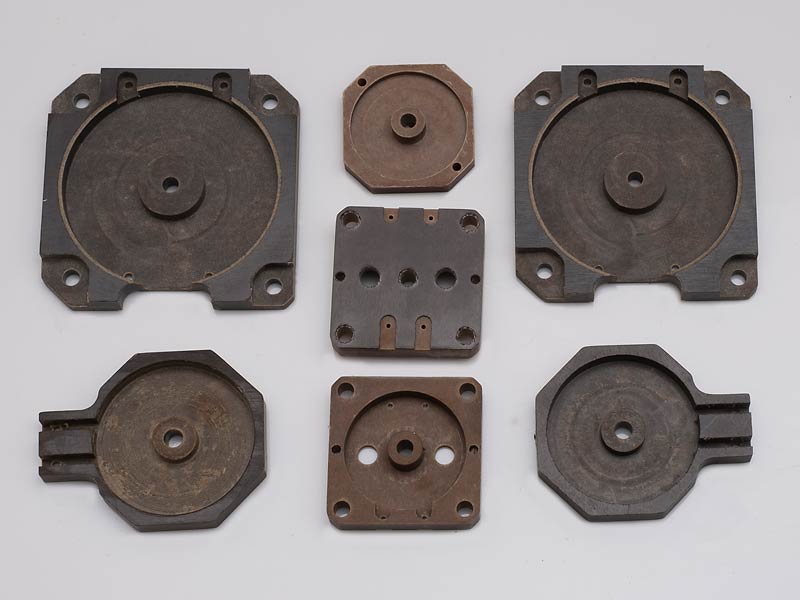

These coil former mounting plates were milled as an array of 6 from SRBP sheet mounted, again, on a vacuum plate. The thickness at the bottom of the cutaways is 1.5mm.

Contact Us for your composite material requirements.

These turned plastic and aluminium components together form a work-holding clamp used when etching glasses.

Contact Us for efficient mixed materials production.

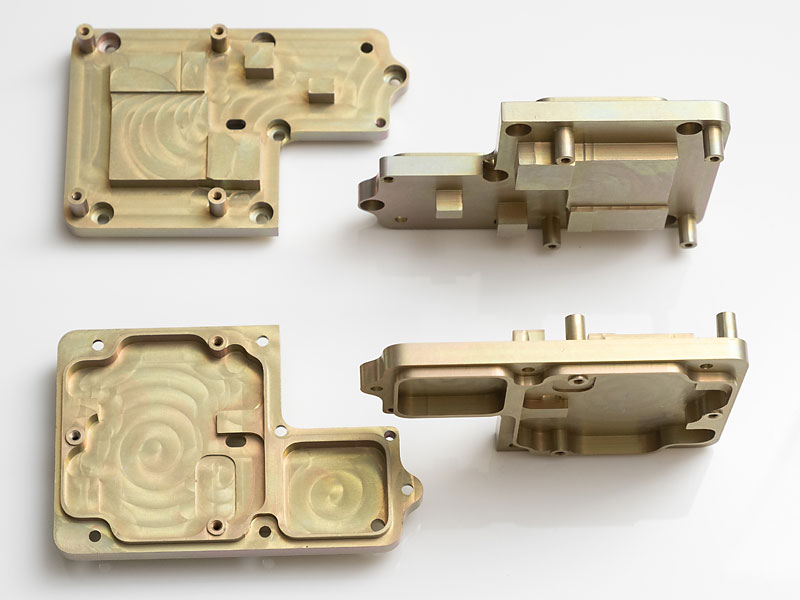

Heatsinks like these would often be extruded in aluminium but extrusion is a high volume process with considerable starting costs. For small batches or prototypes it's often quicker and cheaper to mill from solid.

These components form part of a sealed enclosure so dimensional accuracy is important too.

Contact Us for prototypes and product or process design.

Carneill Precision Engineering Ltd

Unit 9 Fan Road

Staveley

Chesterfield

S43 3PT

e:

Precision machined components in

Sheffield

Chesterfield

Nottingham

Derby

page last updated: 02/07/2020